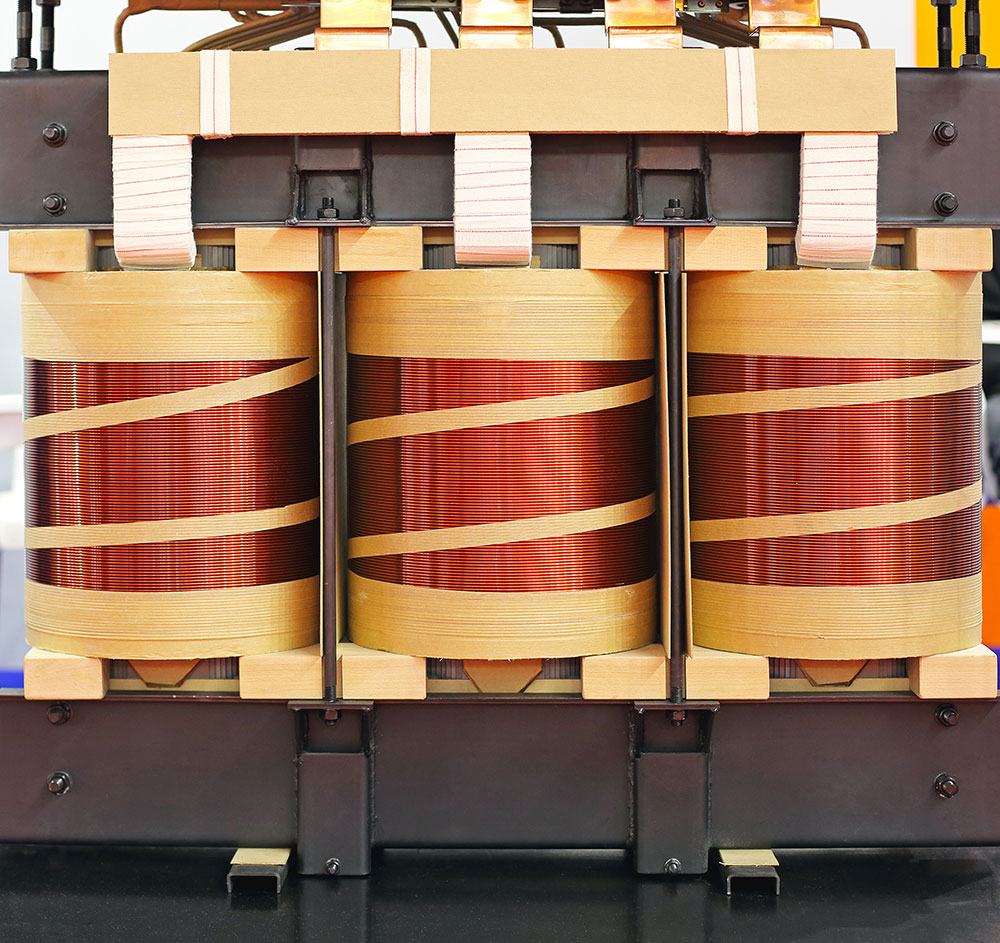

The ISM team designs and manages production of high-quality, cutting-edge transformers for various applications. In particular, we are proud to drive the global solar revolution. Leading inverter manufacturers rely on ISM to deliver their magnetics on-time and on-budget.

ISM Magnetics

Capabilities Include

General

- Advanced core materials: nano-crystalline, amorphous, and super sendust

- Aluminum and copper foil/strip and edge-wound coils

- 200% inspection with professional test lab, including noise and vibration testing

- Automatic and semi-automatic winders for foil widths up to 1.4m

- Vacuum pressure impregnation

3-Phase Transformers & Reactors

- Capacity: 2000 pcs of transformer or reactor per month

- UL recognized insulation system up to 240C (Class S)

- Water cooled reactors

- 3-phase transformers: up to 1500kVA; 99.3% CEC/Euro for solar inverters

- 3-phase reactor: up to 2500A and 40mH; low loss silicon steel and amorphous core options for solar inverters

- CAD and simulation for electromagnetic and thermals

Linear Transformers

- Capacity: 1 million pcs/month

- UL-recognized insulation system up to 240C (Class S)

- Linear transformers: up to 10kVA

ISM Battery

Our battery solutions grew from our long-term core competency in power systems. From traditional lead-acid, to lithium-ion, to other cutting-edge technologies, we can meet any battery customer’s needs and challenges.

Capabilities Include

- Energy storage system manufacturing sites

- Custom battery-management systems and solutions

- Battery cell manufacturing

- Chemistry: Lithium-Ion (Li-Ion) and Lead-Acid (VRLA)

- Cell product portfolio: 18650, 26650, Pouch

- Full testing capabilities

- Dangerous Goods Regulation (DGR) training and certification

- VMI solutions for the storage and handling of Li-Ion cells and systems

AN ISM Example

An enterprise-class OEM was using lead-acid battery technology that was failing in high-reliability applications, forcing customers to perform costly replacements. ISM worked with the customer to implement a program to replace the lead-acid batteries with lithium-ion. The change extended the battery’s useful life to match product in which it was embedded. ISM created financial models that demonstrated the project as an investment that reduced the total product cost. Lastly, ISM and the customer designed an entirely new supply chain which leveraged the lightweight and module lithium-ion design for maximum value.

ISM Power

Power supplies have been a key ISM product for 30 years, and we’re proud to be recognized as an industry leader. We support high-reliability, enterprise class applications and low-complexity, high-volume commercial and consumer products.

Capabilities Include

- AC/DC and DC/DC Power Supplies up to 2200W

- Fan and Blower Packs

- SPS, UPS Battery solutions including lead-acid replacement

- Power Distribution Units (PDU)

- Power Distribution Panels (PDP)

- Self-Certifying UL

- Platinum and Titanium Efficiencies

- Industry-Leading Power Densities

- Analog and Digital

- Internal and External designs

PCBA Capabilities:

- 9 global manufacturing/production sites across Thailand, Philippines, Brazil, Mexico, USA and China

- 10 global research and development sites

- 2 software development sites

- Quality standards: ISO 9001, ISO 14001, OHSAS 18001, Sony GP, QC080000, TL-9000, TS16949, QS9000, ISO 13485

- Safety certifications: UL, TUV, BEAB, JQA, CSA, EMC, CCC – PCBA, Low volume -Hi mix to High Volume – Low mix, SM/PTH/full system assembly

- Full test capabilities including SPI, AOI, X-Ray, ICT, Function Testing and Burn-in/ORT.

- In-House Test Development capability

- In- house Factory Automation group

- plastic injection molding

- metal stamping

- powder sintering

- die casting

- aluminum extrusion

- rubber parts molding

- jig, fixture, and tester design and fabrication

- bar code and RFID product tracking management system

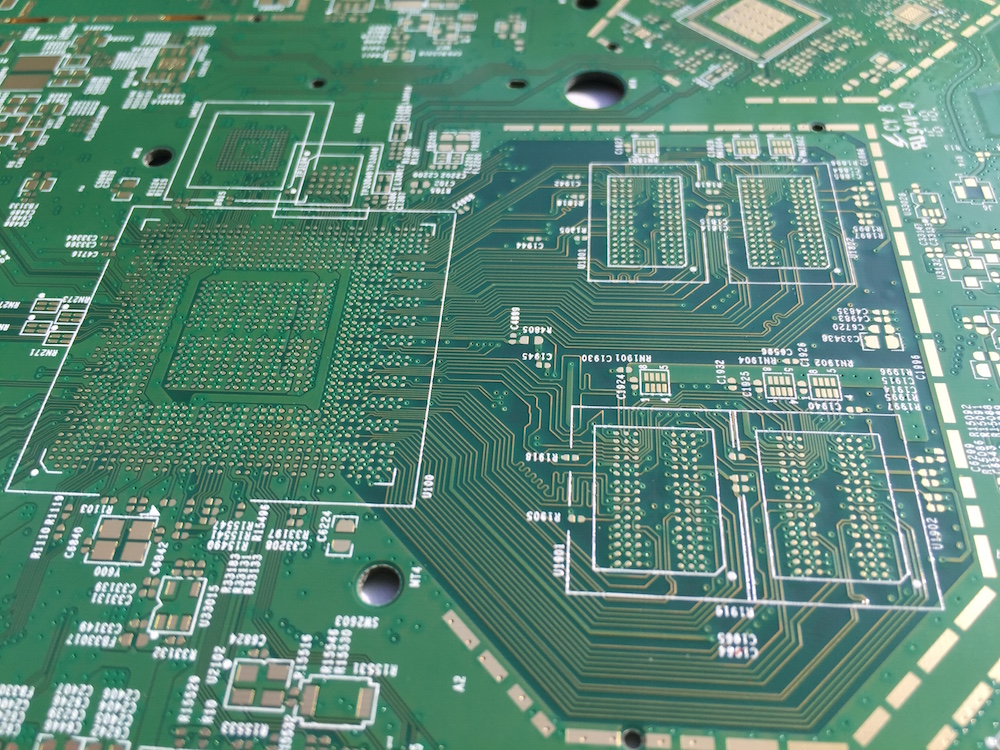

ISM Circuits

The PCB has been at the core of everything we do since our founding. Our business naturally evolved from selling PCBs to also include the next stage, populated boards in completed products. As a value-added service to our customers, ISM conducts DFM/technical review seminars: day-long, face-to-face educational sessions in which our PCB experts meet with the customer’s design and engineering teams to review the technical specifications of their project. We listen to our customers’ unique needs and recommend optimized design solutions. In addition to reviewing such areas as base materials, copper requirements, and PCB design in general, we break down each element to truly understand such aspects as surface finish, solder mask color, impedance requirements, optimal board size, and others. We help customers strike a balance to design better-performing boards that are easier to manufacture, reducing costs and improving internal processes.

PCB Capabilities:

- Manufacturing sites in China and Thailand

- ISO9001:2008, ISO14001:2004, and ISO/TS16949:2009 certified

- Capacity: > 6 million square feet per month

- Prototype through high volume production

- Layer count: 2-20

- HDI: 1+4+1, 1+6+1, 2+4+2, 2+6+2

- VIP technology

- Laminates: CEM-3, FR-4, High Tg FR-4, Halogen-Free, High CTI/Low Dk

- Copper Thickness: 0.5 oz. – 4.0 oz.

- Minimum line/spacing: 3mil / 3mil

- Surface finishes: HASL, Lead-free HASL, OSP, Immersion Silver, Immersion Tin, ENIG, Carbon Ink, Peelable solder mask

- Board Thickness: .012″ – .125″

ISM Solar

ISM Solar Development builds solar energy systems that deliver clean energy savings to communities and public and private users throughout the country. Its mission is to Bring Land to Light – repurposing underutilized and compromised space, including landfills and brownfields, in pursuit of a sustainable energy economy.